Building your own RC car can be both exhilarating and rewarding. It involves piecing together various components, such as electric motors, remote controls, and custom-made chassis, to create a personalized radio controlled car. Whether you’re a hobbyist looking to delve into the world of DIY RC toys or an experienced constructor aiming to design a unique vehicle, this guide will walk you through the process. You’ll learn about the essential parts, the assembly process, and the satisfaction of testing your newly built RC machine. With some patience and creativity, you can create an RC car that stands out at the track or in your collection.

Understanding the Basics of Remote Controlled Cars

Before diving into the assembly of your own RC car, it’s important to comprehend the fundamentals. Remote controlled cars, or RC cars, are miniature vehicles steered using a radio-frequency link between a handheld transmitter and a receiver board within the car. Choice plays a significant role in RC construction; whether opting for an electric or nitro-powered vehicle each will need a different setup and handling approach. Ensuring that you have a dedicated workspace and the right tools before you begin is essential for a smooth and enjoyable building experience.

Gathering Your Materials

The construction of an RC car necessitates a collection of core components. The heart of most radio controlled cars is an electric motor, which will need a reliable battery source and appropriate speed controls. When choosing the chassis, consider using materials that are both lightweight and sturdy, like carbon fiber or aluminum. Here is a basic list to get you started:

- Motor (Electric or Nitro)

- Battery Pack (LiPo/NiMH)

- Electronic Speed Control (ESC)

- Receiver

- Chassis

- Suspension System

- Tires and Wheels

- Remote Control Transmitter

Choosing the Right Remote Control System

A good remote system is key to precise and responsive control over your RC car. The market offers a variety of transmitters, from basic units perfect for beginners, to advanced radios allowing for detailed adjustments. It’s crucial to select a system that works on a clear frequency to avoid interference. Consider the following when making your choice: range, channels, ergonomics, and the inclusion of programmable features.

Step-by-Step Guide to Assembling Your RC Car

Your RC car’s performance is largely dependent on its chassis, the base frame to which all other components will be attached. Start by either building a custom frame or modifying an existing one from an RC kit. Precision in this step is key; making sure that the chassis is symmetrical and balanced will lead to better handling. Close attention to alignment could mean the difference between a car that soars and one that stumbles.

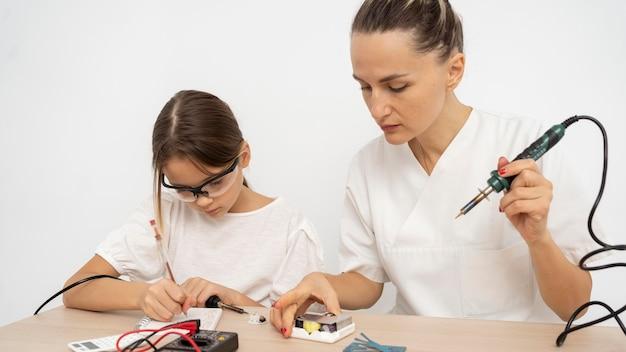

Installing the Motor and Electronics

Once your chassis is ready, it’s time to install the motor. Secure the motor in place, then proceed with the wiring. Each component should be connected precisely to the speed controls and the battery. This is a delicate process that requires focus as improper wiring could lead to failures or even hazards when using the car. Keep the electronics neat, securing loose wires to prevent snags and damage during operation.

Assembling the Drive System

Connecting the motor to the wheels is achieved through a series of gears and shafts known as the drive system. Match your gear ratios to the desired performance; lower for acceleration, higher for top speed. Fit the driveshafts carefully, making sure they rotate smoothly and are well lubricated. This will enable efficient power transfer from the motor to the wheels, which is crucial for responsive control.

Fitting the Wheels and Suspension

Choosing the right wheels and constructing a robust suspension system are pivotal for the adaptability of your RC car to various terrains. Install durable tires that offer good grip and balance. The suspension system should be flexible enough to absorb shocks but also firm to maintain stability. Test the wheel alignment, and adjust the suspension settings to find the optimal ride height and damping for your specific usage.

Syncing the Remote Control System

Perhaps the most satisfying step is syncing your remote control transmitter with the car’s receiver. This bridges the gap between user input and vehicle action. Follow the manufacturer’s guidelines to establish a connection. If you experience issues with pairing, refer to the troubleshooting tips in your user manual. Good remote syncing means less lag and more precision in controls, translating to better performance.

Customizing and Testing Your RC Car

With the technical aspects complete, you can focus on the aesthetics and enhancing the performance of your RC car. This could range from applying a vibrant paint job to integrating high-grade alloy components. Custom decals can also be applied to show off your style or model’s branding. Remember that these enhancements should not impede the functionality of your RC vehicle.

Safety Checks and Pre-Flight Tests

Before taking your creation out for a spin, it’s important to perform a thorough safety check. Look for any loose parts, and ensure all electronics are properly secured. Your pre-run checklist should look something like this:

- Ensure all screws are tightened.

- Check the motor’s temperature.

- Test the brakes and throttle response.

- Inspect the battery connections.

- Verify the range and responsiveness of the remote control.

This list helps avoid accidents and ensures a fun, safe experience every time you run your RC car.

Conclusion

Building a remote-controlled car from scratch is an incredible journey that blends creativity, technical skill, and passion for RC toys. It allows for an intimate understanding of the mechanics and electronics that make up controlled toys. The process may be challenging at times, but the result will be a machine that not only runs but tells a story of your determination and ingenuity. The RC community is vast and supportive, offering opportunities for shared ideas and thrilling competitions. Your own RC car is not just a toy; it’s a testament to learning and accomplishment.

| Type of Tool | Description | Use Case |

|---|---|---|

| Screwdriver Set | Variety of sizes and heads | For assembly and adjustments |

| Soldering Iron | For electronic connections | Wiring motors and speed controls |

| Pliers | Nose and wire cutting pliers | Manipulating small parts and wires |

| Hex Wrenches | Metric and standard sets | Securing bolts and nuts |

| Tweezers | Precision and standard tips | Handling small components |

| Multimeter | To check electrical connections | Testing before operation |

FAQs

Q1: What is the most suitable type of motor for a beginner’s RC car?

A1: A brushed DC motor is a good choice for beginners due to its simplicity, ease of use, and cost-effectiveness.

Q2: How long does it typically take to build an RC car from scratch?

A2: The time can vary widely depending on experience and the complexity of the design, but on average, it can take anywhere from a few hours to a few days.

Q3: Is it more cost-effective to build an RC car from scratch or to buy a pre-made one?

A3: It can be more cost-effective to build an RC car from scratch, especially if you source parts separately and focus on budget-friendly options. Additionally, you can customize your car to your own specifications.

Q4: Can I use 3D printed parts for my RC car?

A4: Yes, 3D printed parts are increasingly popular for custom RC car builds, allowing for a high degree of customization and unique design features.

Q5: What is the most important factor to consider when building a remote controlled car?

A5: One of the most important factors is the balance between the weight and power of your RC car, as this affects its speed and maneuverability. Additionally, ensuring that the electronic components are correctly installed and protected is critical for the functionality and longevity of the car.